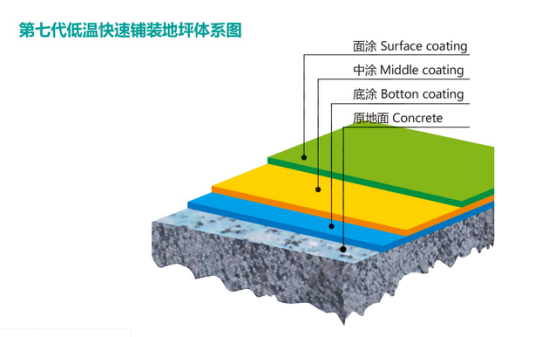

Polyurethane mortar floor is a self-leveling, medium to heavy-duty, single-color, four-component, water-based polyurethane-based, cement and aggregate mortar layer with high wear resistance, impact resistance, chemical resistance and resistance to other physical erosion. performance. Polyurethane mortar floors are beautiful, easy to clean, and have smooth aggregate texture. The coating thickness is 4-6 mm.

Characteristics of polyurethane mortar floor

Polyurethane mortar floor has the characteristics of high temperature resistance of 115℃, acid and alkali resistance, oil resistance, and heavy load resistance.

Advantages of polyurethane mortar floor products

Resistant to various organic and inorganic acids, alkalis, amines, salts and solvents. Resistant to grease.

The thermal expansion coefficient is similar to that of concrete. It maintains the same displacement as the base during normal thermal cycles and is not prone to cracking. And maintain its physical properties in the temperature range of -40ºC to 115ºC.

The bond strength is greater than the tensile strength of the concrete (the concrete fails first). Good overload performance.

Tough when impacted/deformed and will not cause cracks or delamination.

It has high wear resistance due to its pure silicon aggregate structure. Easy to maintain.

Scope of application of polyurethane mortar floor

Polyurethane mortar floors are mainly used in workshops that require heavy-duty vehicles to pass through; workshops that require oil resistance; workshops that require high and low temperature resistance and acid and alkali resistance: food processing plants, wet and dry processing areas, refrigeration & freezing areas, dairy plants, Breweries, distilleries, laboratories, chemical processing plants, pulp and paper mills, warehouses and storage areas.